-

- Accueil

- Machines neuves

- Machines d’occasion

- Rectifieuses

- FRAISAGE

- CONVENTIONNEL

- CENTRE USINAGE VERTICAL 3 AXES < 1000 mm

- CENTRE USINAGE VERTICAL 3 AXES 1000 à 2000 mm

- CENTRE USINAGE VERTICAL 3 AXES > 2000 mm

- CENTRE D’USINAGE VERTICAL PALLETISE

- CENTRE USINAGE VERTICAL 4 AXES

- CENTRE USINAGE VERTICAL 5 AXES

- CENTRE HORIZONTAL

- CENTRE PORTIQUE

- PETITES FRAISEUSES CNC

- FRAISEUSE ALESEUSE

- ALESEUSE

- FOREUSE

- TOURNAGE

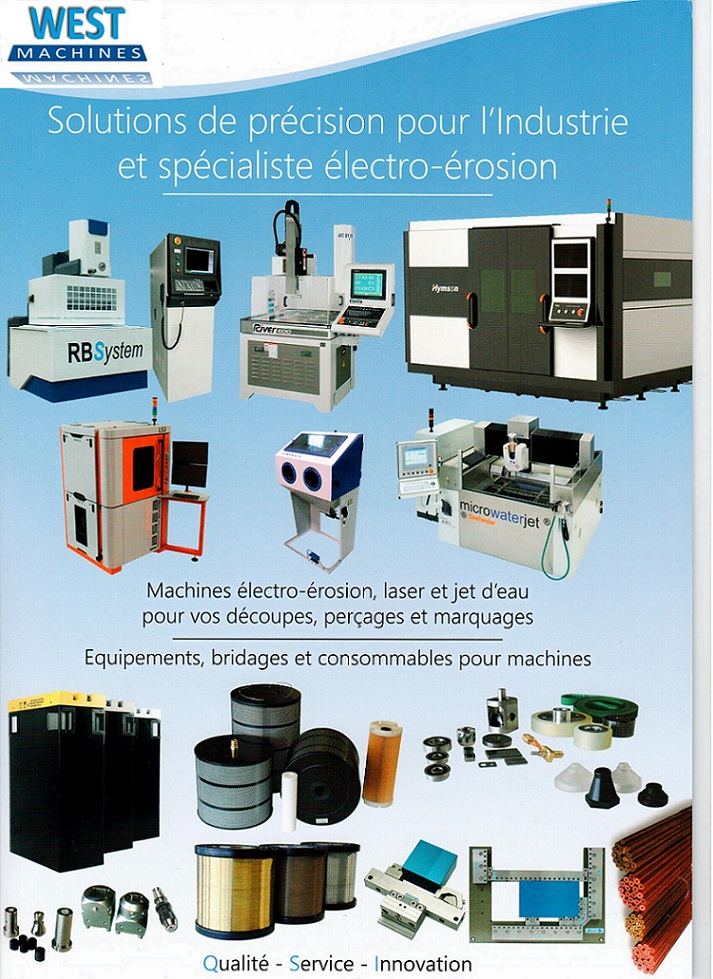

- EROSION

- CONTROLE

- TOLERIE

- TAILLEUSES DE DENTURES

- MATERIEL DE MANUTENTION

- SERVICE & EPI

- EQUIPEMENTS BRIDAGES

- VISUALISATION TOURNAGE ET/OU FRAISAGE NEWALL

- OUTILLAGE – MACHINES A FIL

- OUTILLAGE – MACHINES 5 AXES

- FIL LAITON – FIL CUIVRE – FIL REVETU ZINGUE

- TRAITEMENT DE L’EAU DES MACHINES A FIL – E.K.O IONISER – RESINE – FILTRES (AGIE CHARMILLES,MITSUIBSHI,SODICK,FANUC, etc ——)

- MICROBILLEUSES & MEDIAS DE MICROBILLAGE

- Contact

-

- Ma sélection (0)

-

Tel : +33 (0) 9 65 34 64 11

Fax : +33 (0) 2 40 71 82 43

Port : +33 (0) 6 09 70 57 59

Fax : +33 (0) 2 40 71 82 43

Port : +33 (0) 6 09 70 57 59

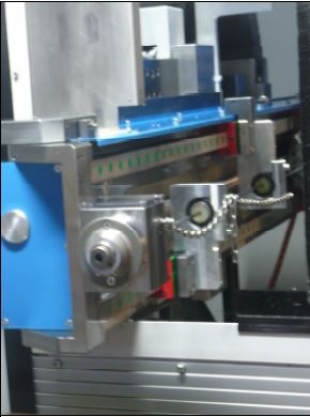

FOREUSE CNC NEUVE BUCK-UHLY TB 1050 CNC – 1000 X 800 X 1050 MM

- GENRE : FOREUSE CNC

- MARQUE : BUCK-UHLY

- TYPE : TB 1050 CNC

FOREUSE CNC NEUVE

MARQUE : BUCK-UHLY

TYPE : TB 1050 CNC

1.0 Examples of work

– General tapping and drilling work with use of conventional Tools

– Deep hole cutting with use of carbide single lip drill bits, e.g. cooling channels,

– ejectors, oil and lubrication drilling

– General light to medium milling work, e.g. circular and rectangular pockets

2.0 Description of machine

– 4 CNC axes (X-,Y-,Z- and W- ) controlled deep hole drilling machine

– Digital drive technology

– Internal coolant feed of up to max. of 80 bar/100bar

– High pressure coolant system

– Chip conveyor

– Drill bushing carrier in heavy duty design incl. chip sluice for direct sport

– drilling with ELHB* up to ø 25 mm

– Co-driven double supporting bezel

– Torque and feed control for deep hole drilling

– V24/RS-232-C interface

– Deep hole technology program

– CE-compatible machine part panelling

3.0 Design of basic machine

– Compact, stable welded design with high rigidity and high damping

– properties

– Low-tension annealed

– Damping critical parts (e.g. extension arm) are filled with special concrete

3.1 Drilling and milling spindle

– Tool Holding Fixture ISO 40 DIN 69871

– Permanent grease lubrication up to 8000 rpm

– Internal coolant feed through the spindle

– Manual tool clamping

3.2 Guidance system

– Generously dimensioned linear guides with pre-stressed roller shoes for exact

– guidance of movement axes

– Ground, pre-stressed ball drives in the X-,Y-,Z- and W-axes

– Guidance systems, actuators and sensors are covered so that they are protected against chips and dirt

3.3 Feed drives

– Highly dynamic, digital feed drives in all linear axes

3.4 Machine covers

– CE compliant partial machine cladding including safety fence

4.0 High-pressure coolant system (double-walled)

– Filtration via a monitored filtration system

– Filtration system consisting of paper tape deep-bed filter

– Enclosed coolant circuit pressure: 0-90 bar

– Pump rate: 0-40 l/min

– Coolant pressures infinitely adjustable via frequency inverter

– Coolant tank volume: approx. 1000 l

4.1 Chip conveyor

– Chip conveyor belt scraper with connected immersion pump with recycling of chips and drilling emulsion; ejection height : 1020 mm

5.0 Process monitoring

– The feed control monitors the feed force during the drilling process

– Automatic shutdown when the values are above or below the preset boundary values

– The current feed values are transmitted in the form of a curve graphic on the screen

6.0 CNC- Control

– Heidenhain iTNC 620 CNC

– Linear interpolation in 3 axes

– Graphic screen LCD/TFT)

– Dialog programming incl. 2D3D simulation graphic

– Data interfaces: one V.24/RS-232-C and one V.11/RS-422

– Direct spindle and feed programming

– Sub-program technology

– Milling and deep drilling machining cycles

– Thread cutting without compensating chuck

– Thread milling

7.0 Technical description

– Working ranges

Table X-axis (transverse) 1000 mm

Drilling unit Y-axis (vertical) 800 mm

Drilling unit Z-axis (drilling depth) 1050 mm

Table W-axis (longitudinal) 500 mm

Drilling depth in one pass with 2 supporting 810 mm

bezels (transverse)

– Greater drill depth possible after resetting

Drilling depth in one pass without supporting

bezels (transverse) 1050 mm

– Greater drill depth possible after resetting

– Manual rotary table

Clamping area LxB 1500 mmx1000 mm

Table load (centre) maximum 2500 kg

T-grooves Number/size 5/14H 12 mm

Rotary range Degree 0-360°

AC main spindle drive

Spindle power at 40% ED 7.0 kW

Spindle power at 100% ED 5.5 kW

Spindle speed directly programmable 0-4000 rpm

Tool chuck SK 40 DIN 69871 A

– Rapid traverse X-/Y-/Z-axis 10 m / min.

– Coolant device

Rinsing pressure through IK adjustable 0-90 bar

Rinsing rate through IK maximum 40 l / min.

Tank volume Coolant tank 1000 l

– Power lines

Mains connection Standard 400 V/50 Hz

Power intake Standard 35 kVA

Compressed air Standard 6 bar

– Space requirement LxBxH after plan

– Work performance

ELHB* from ø 4-32 mm

tapping to M24, greater

threading by

thread milling

milling to 120 cm³

8.0 Basic price

– ex works Germany euros HT : On request

9.0 Accessories/Options

– Services *– Machine installation on site : On request

– 3 training day on site : On request

More options and technical changes, available on demand

Conditions of delivery and payment : on demand

Machine colour :

RAL 5015 (sky blue) / RAL 7035 (light grey)

PRIX : Contactez-nous

|

|